Hydroblasting is proven to be the best method of carrying out runway rubber removal, line/paint removal & retexturing treatments as it maintains the integrity of the road or runway surface. Works are carried out in the most environmentally friendly way as machines use clean water without any additives and return used water, through the on board pneumatic system, to the waste tank. This can then be disposed of in accordance with Environment Agency regulations and our waste carriers licence.

FCL operate 3 ultra high pressure (UHP) water jetters to carry out Hydroblasting treatments to roads and runways. They operate at controlled pressures up to 3000 bar with UHP water being produced by the latest generation of URACA pumps, renowned for their reliability. For design and manufacture of the machines we have worked in partnership with leaders in the sector, Jetting Systems in the UK, for almost 2 decades. We are constantly carrying out research and development alongside Jetting Systems Ltd to ensure we continue to operate at the forefront of the industry.

Oil Spill Cleanup

Our hydroblast machines can also provide an emergency fuel spill clean-up service. With capacity of cleaning oil spillages over an approximate area of 400m2 in an hour they can provide the most efficient service in terms of environment, time and cost.

Runway Rubber Removal

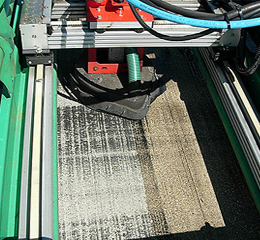

Optimum rubber removal is achieved through the management of speed, pressure and water flow.

Each unit features a cleaning head with multiple nozzles rotating about a vertical axis and controlled by computer. The shape of the head and the configuration of nozzles, resulting from research and trials, provides maximum cleaning efficiency. The head moves within a frame in an X pattern so that its cleaning sweeps are always at 90° to the direction of travel of the jetting unit – running parallel to the runway grooves stripping out all the deposited rubber.

If the runway is required at short notice for air traffic movements our machines can vacate the runway within one minute leaving only a damp surface.

Runway Rubber Removal at RAF Lyneham

Road Marking / Paint Removal

For removing road markings or other paints on surfaces we use the purpose built “Raptor” which is a highly manouverable small buggy unit featuring a zero- turn turning radius allowing our experienced operator to remove paint in the tightest of places. Raptor is connected by umbilical electric cables, UHP water hose and waste extraction hose to our jetting unit which provides the required UHP water.

The Raptor operator and the driver of the water jetting unit work together in radio communication via headsets which aids efficiency and is an important contribution to the safe operation and precision of the system.

For the lining renewal element of works packages we work in close partnership with our supply chain.

Hydroblaster prepared for operation to remove line markings

Removing thermoplastic markings

Removing thermoplastic markings

Surface Retexturing & Cleaning

Certain new asphaltic surfaces tend to be rich in binder, particularly Stone Mastic Asphalts. Although the excess binder will wear off with trafficking it presents low early life skid resistance. UHP water jetting will bring such surfaces within acceptable levels of SCRIM and texture depth.

Our machines were able to provide a vital function on the new £745million Aberdeen Western Peripheral Route between June 2017 and May 2018. We treated 58km of new dual carriageway in each direction removing latency from the slip-form concrete pavement at the rate of up to 800 sq. metres per hour.

One key element of the project was to ensure environmental compliance and 26,000 litres of waste water used daily during the operation was removed by vacuum tanker for specialist disposal.