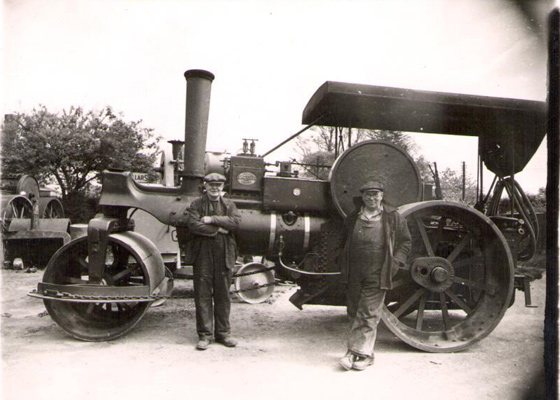

Incorporated in 1911 as the Essex Steam Rolling Association Ltd, Foster Contracting is the UK’s longest established installer of Asphalt Geosynthetics and has an unrivalled track record in road and runway maintenance.

More than a century of industry leading expertise

Throughout our long history we have always strived to be at the forefront of the industry. With a reputation for delivering quality services at the right price and a dedication to designing and building industry leading equipment we build long-lasting relationships with our clients.

Dedicated staff work closely with clients to help them plan, install and maintain roads and runways and are always on hand to provide expert advice. The modern fully equipped workshops are staffed by engineers who are kept up to date with the latest developments both technically and with health and safety matters. Our services include Retexturing, Rubber Removal, Asphalt Geosynthetics, Bond Coat Spraying, Joint Spraying and Surface Dressing. So no matter what stage of its lifecycle a surface is in we can ensure that it remains safe and reliable for as long as possible.

With depots in Essex and Perthshire we deliver unrivalled services throughout the UK.